Given the rapid advancements being made in new technologies like artificial intelligence and robots, a variety of predictions have been made about how employment will change in the future, from the optimistic to the pessimistic. The digitalization of work is also expected to significantly affect employment in the future.

This paper examines the experience of adopting robots in Japan and conducts an empirical analysis of the effect that automation has had on employment. As Japan incorporated industrial robots in a serious way starting in the 1970s, before other advanced countries, it has a long history of adopting robots. Also, the Japan Robot Association maintains long-term data regarding industrial robots, which is suitable for investigating the effect of these new technologies on employment.

The problem that occurs when investigating the effect that the adoption of robots has on employment is that the amount of employment and the number of robots are determined simultaneously. For example, if demand in the automobile industry is strong, the recruitment of human workers and investment in robots will both increase at the same time. As such, we cannot exclude the possibility that, if no robots had been adopted to begin with, employment may have grown further than it did. To deal with this problem, we focus on changes in robot prices. If robot prices decrease, it is because the adoption of robots has advanced independently of product demand. We are able to calculate the price of a single robot based on number of units shipped and order prices, which are recorded both by robot task and by intended industry in digitalized Robot Association data. Examining these changes in robot price, we can see that changes in robot prices faced by each industry have differed. For example, while the price of welding robots, which are primarily used in the manufacturing of transportation machinery, have uniformly fallen from 1982 until recently, price reductions for assembly robots, which are primarily used in the manufacturing of electronic devices, have been limited. Using these fluctuations in robot prices that vary by industry, we investigated the effect on employment in each industry of the adoption of robots by each industry.

The results of the industry level analysis indicate that the number of robots increased by 1.54% for each 1% reduction in robot price. They also indicated that, simultaneously, a 1% reduction in robot price led to a 0.44% increase in employment. Combining these results, we can see that a 1% increase in robots led to a 0.28% increase in employment.

Furthermore, in order to compare these results with those of previous research in the US, an analysis was performed in which the observational unit was changed from by industry to by commuting zone. The analysis results indicated that an increase of 1 robot per 1,000 workers increased employment by 2.2%. This compares with the estimation results from Acemoglu and Restrepo (2020) in the US which found a 1.6% decrease in employment. The reason for this variation in results may be that, first, industries such as automobiles and electronic devices were continuously increasing production during the period of stable growth in the 1980s following the oil shock, which was when robots were first adopted. In this environment, a lack of labor was an impediment to growth, and the adoption of robots reduced labor costs making low-cost production possible and expanding the scale of production. The connection between cost reductions accompanying the adoption of robots and the maintenance of domestic production may also be important. Although the labor substitution accompanying the adoption of robots reduces employment, the effect of maintaining and expanding the scale of production via lowered production costs is significant, which may lead to an ultimate increase in employment.

In considering how the adoption of new technologies affects employment, the example of robots contains a wealth of suggestions. While a direct effect exists in which the adoption of new technologies reduces the number of jobs available to humans, the adoption of new technologies is connected to reduced costs, and an indirect effect in which employment is increased through the expansion in production scale can be expected. That is, the question of whether the adoption of new technologies increases employment depends upon whether an increase in productivity causes an expansion in production scale. If the production scale does expand, then employment opportunities expand with it, and improvements in working conditions, such as wages and working hours, can also be expected.

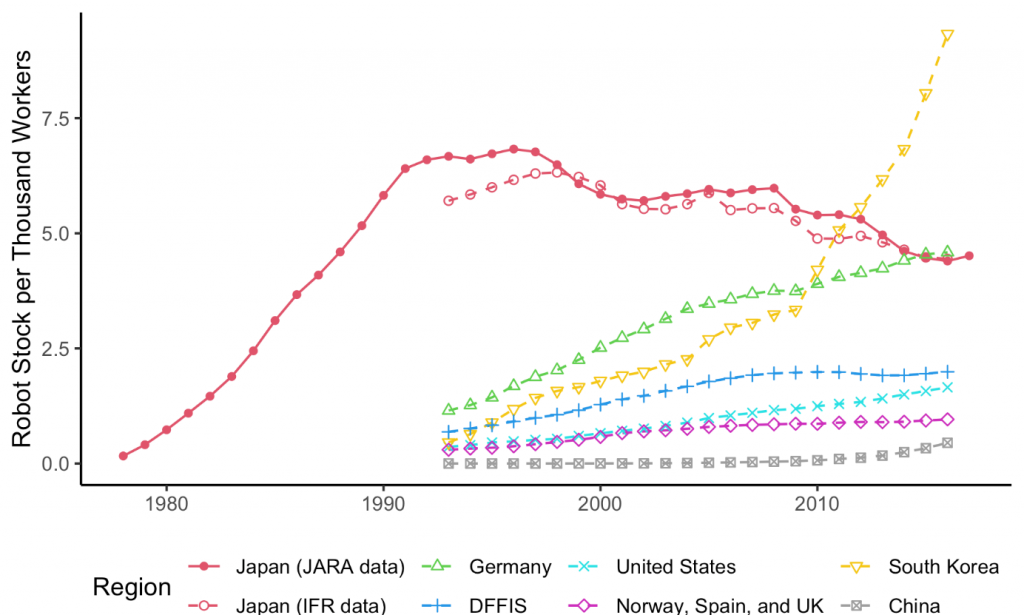

Number of robots per 1,000 workers. Calculated by the author based on data from the Japan Robot Association, International Federation of Robotics, OECD, and National Bureau of Statistics of China. Time series data for number of robots in each country or region are shown. For Japan, data from both the Japan Robot Association and International Federation of Robotics are reported. The difference in the data sets is due to a small difference in the robots that are included in the figures. Data for the Japan Robot Association is the number of robots shipped domestically by Japanese robot manufacturers from 1978 to 2017, with stocks calculated under the assumption of complete and immediate depreciation after 12 years. Data from the International Federation of Robotics is data for stocks of robots from 1993 to 2016. DFFIS stands for Denmark, Finland, France, Italy, and Sweden. The number of robots for each country is divided by the number of workers. Employment data is based on OECD figures, except for in the case of China. Employment data for China is based on the National Bureau of Statistics of China.